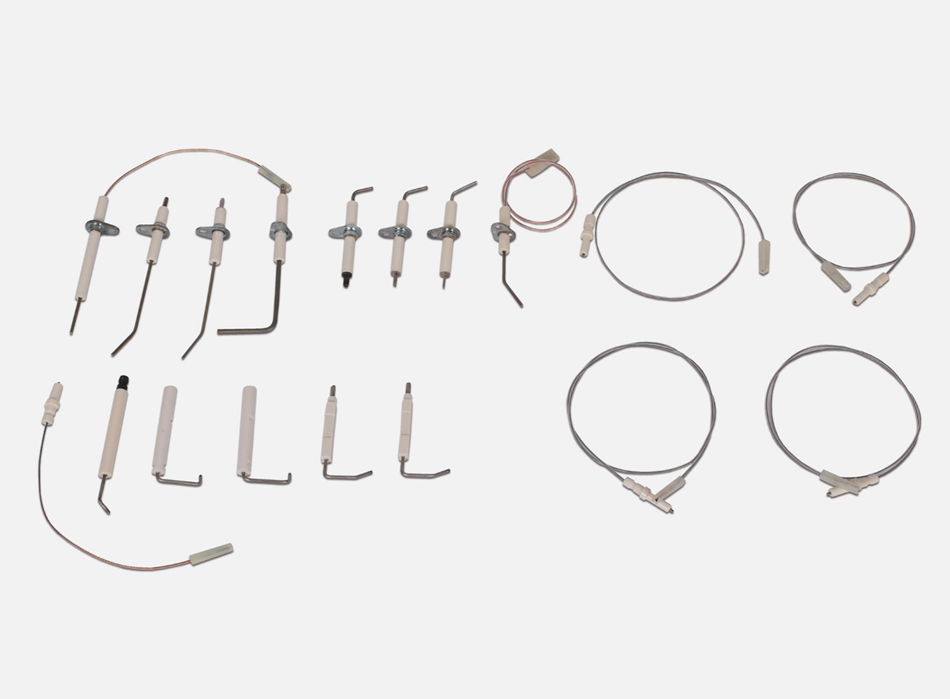

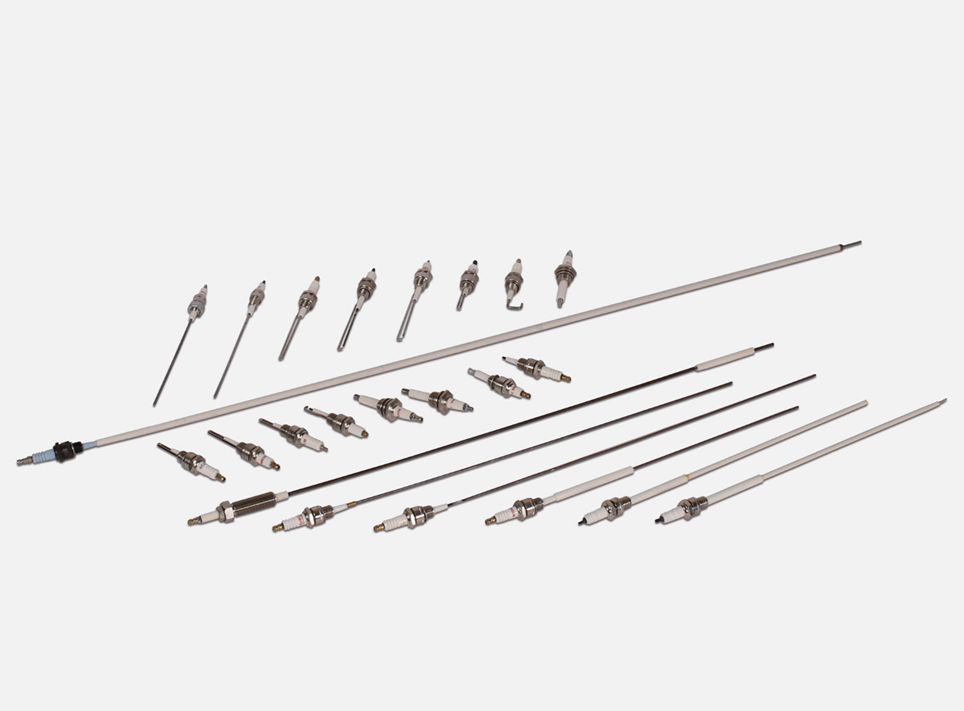

Ignition electrodes for industry and households

We manufacture ignition electrodes with different designs and different dimensions, which provide practical and useful opportunities for both industry and households.

We have standardized ignition electrodes and we also produce according to customer requirements.

Function

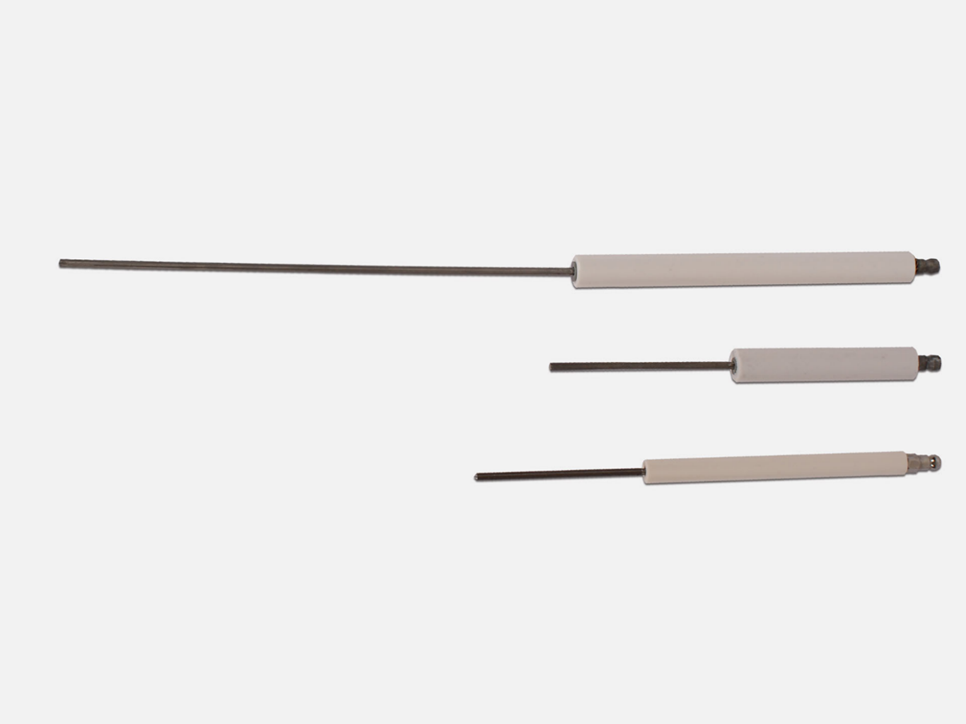

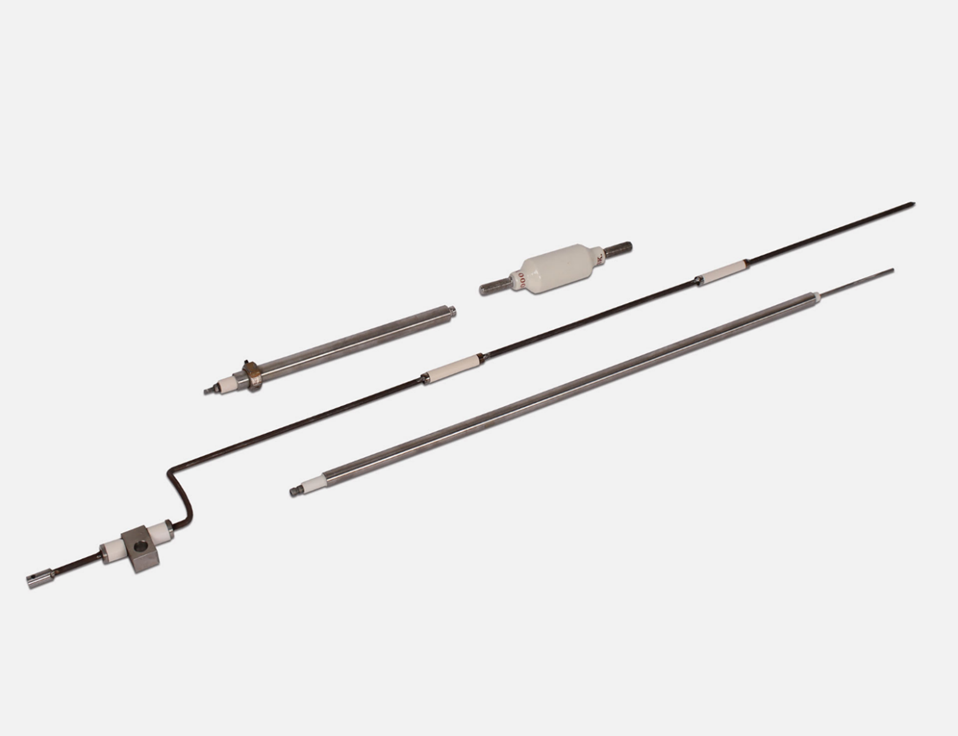

The easiest way to ignite fuel is via high-voltage systems, which conduct electric current (voltage ≈10KV) to a pair of insulated electrodes. Gaps between the electrodes are adjusted in such a way that the spark forms in the vicinity of the burner nozzle. Dependence on burn will be between rooms max 5mm. In the case of different types of construction, there may be only one electrode (lighter).

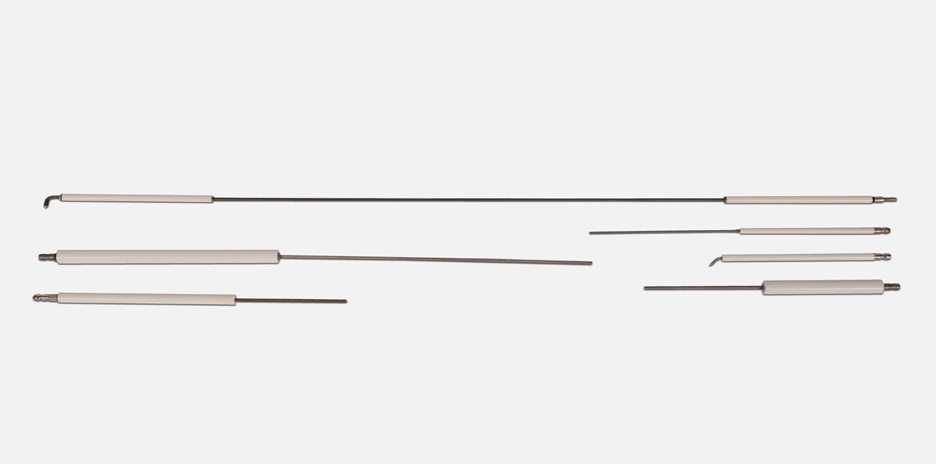

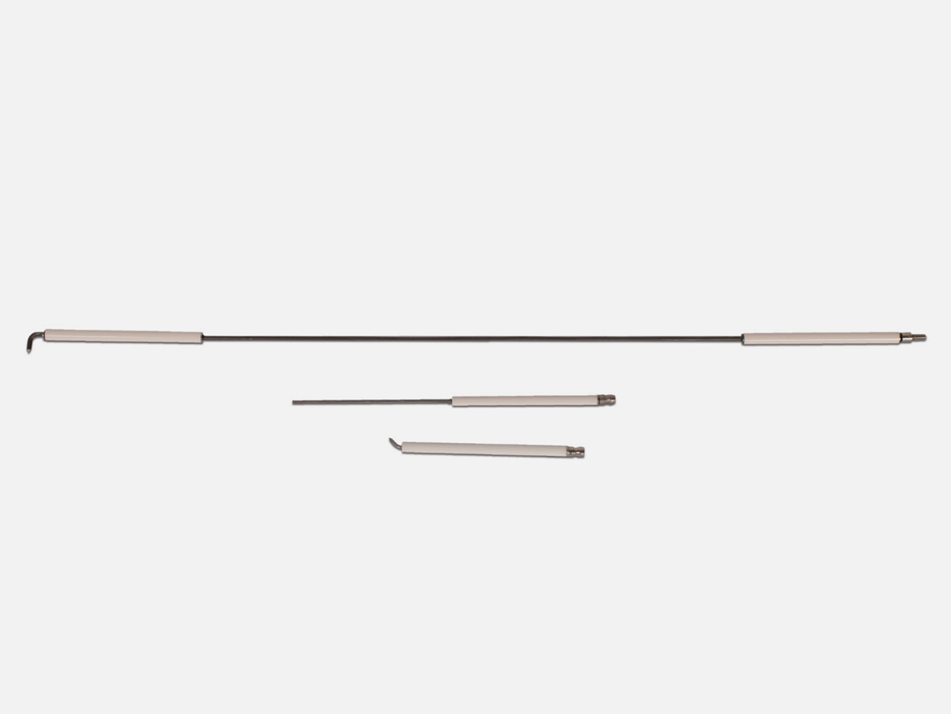

Central electrode and insulator

Ignition electrodes usually consist of two parts: a center bolm, which is a thin metal rod, and a grounding point, which is a wide metal base. The central part is often made of materials with high heat resistance, such as kanthal, Ni-Cr alloys iridium or platinum,

The electrode has great resistance to high temperature, corrosion and electrical erosion.

The insulator of the lighters is made of ceramics with 95% Al2O3. Ceramics have very unique mechanical, chemical, thermal properties.

In addition to standard lighters, we also manufacture lighters according to special customers’ wishes on the basis of the attached sample or technical documentation with operating and installation parameters

(operating pressure and temperature, current voltage, terminal end type, presence of moisture and aggressive media, dimension and the like)