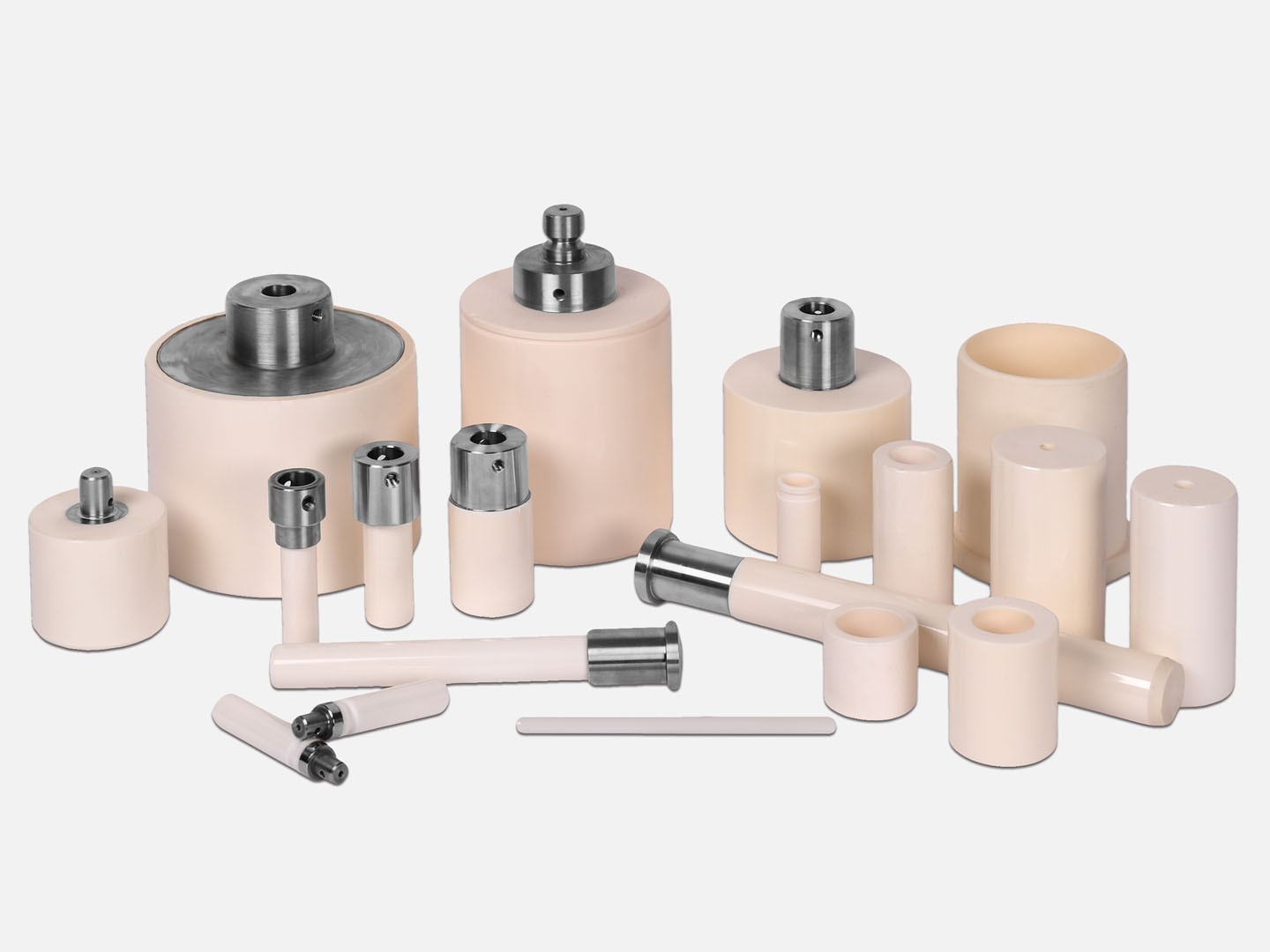

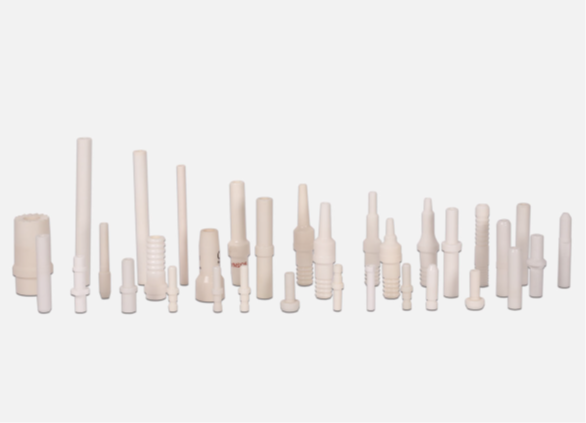

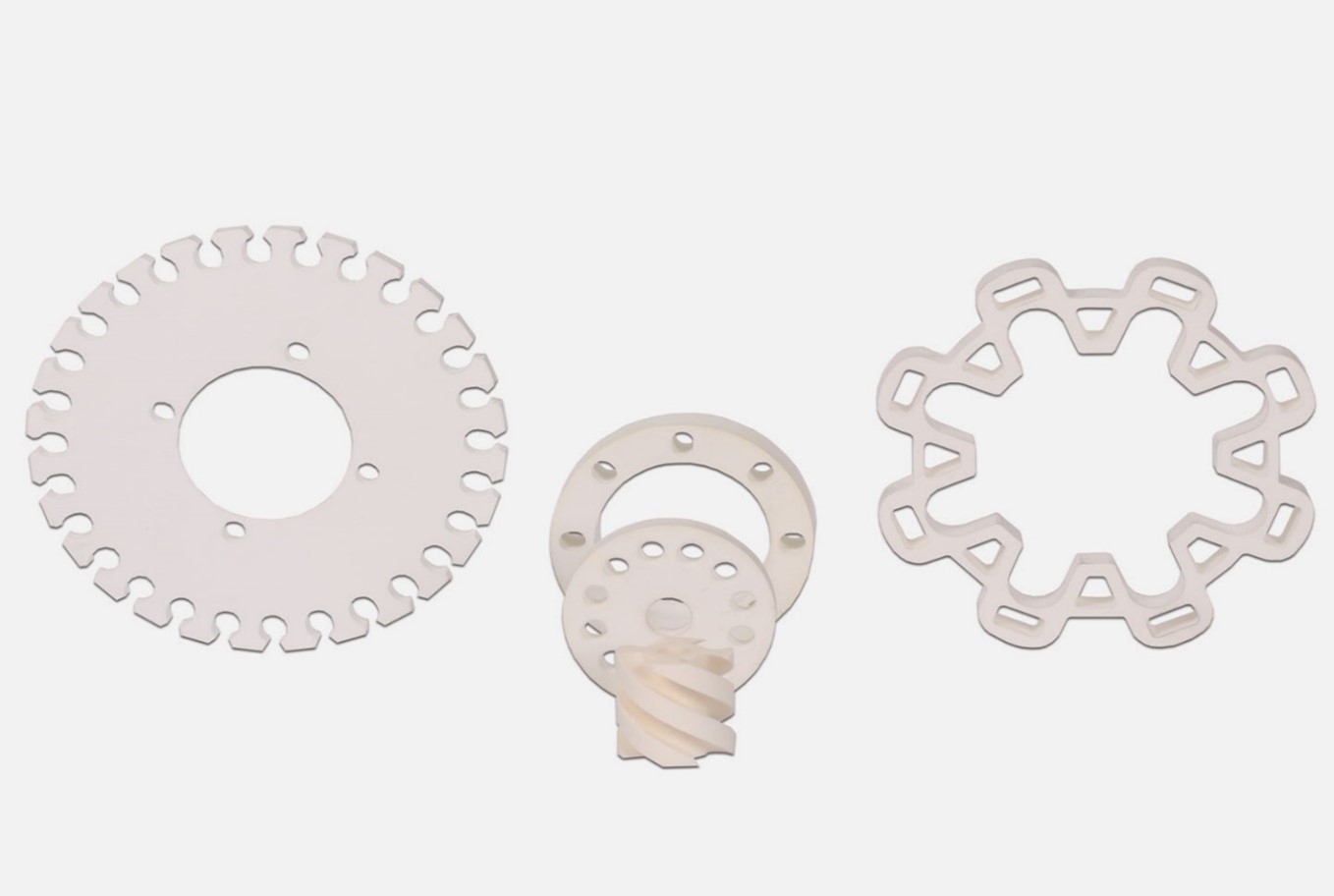

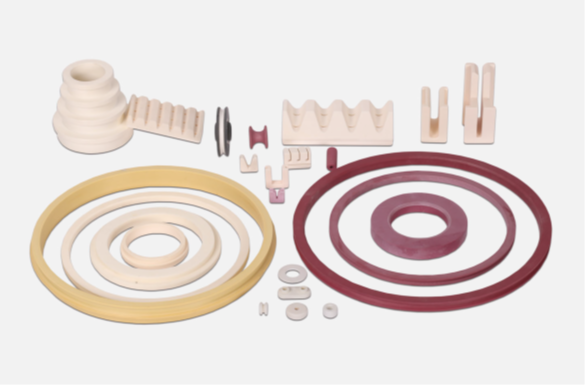

Ceramics are used in the wire industry to facilitate the production of wire products. Usually, ceramic parts such as the wire running eye and wire tension wheels are used. These components are made of technical ceramics and play an important role in ensuring that the wire is pulled evenly and smoothly through various processes such as drawn, twisted, or machined.

Ceramic wire running eyes are known for their high hardness and low friction properties, which reduce wear on the wire and improve its strength and quality. They are valuable in high-speed applications where the smoothness of the wire is crucial.

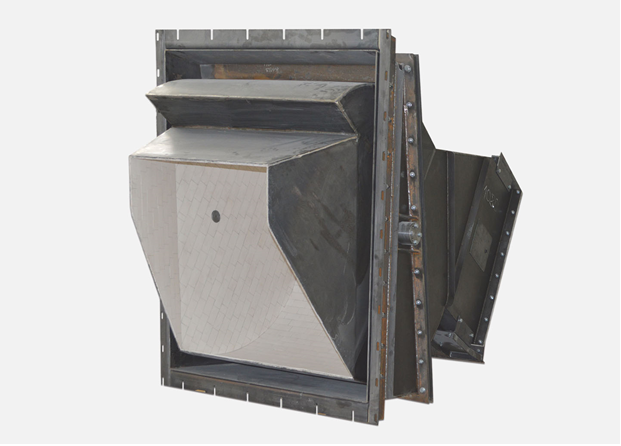

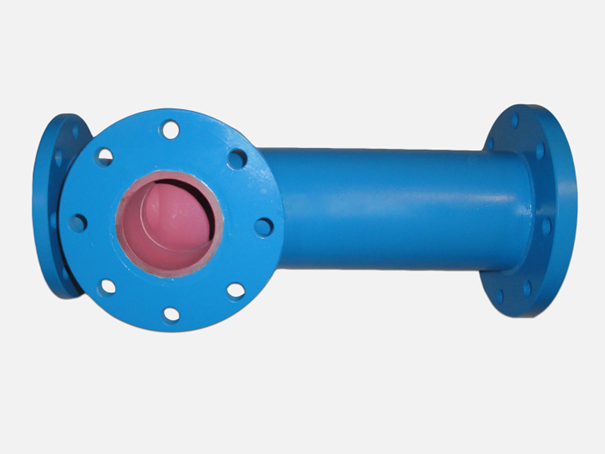

Wire tension wheels made of ceramics offer excellent wear resistance and the ability to withstand high temperatures. These wheels help maintain the correct tension on the wire during production, which is crucial to avoid damage and unwanted variations in the properties of the thread.

In summary, ceramics in the wire industry is an important component for achieving high-quality wire products and efficient production. Its unique properties, including hardness, low friction and thermal stability, make it an ideal choice to meet the demanding demands of the industry.