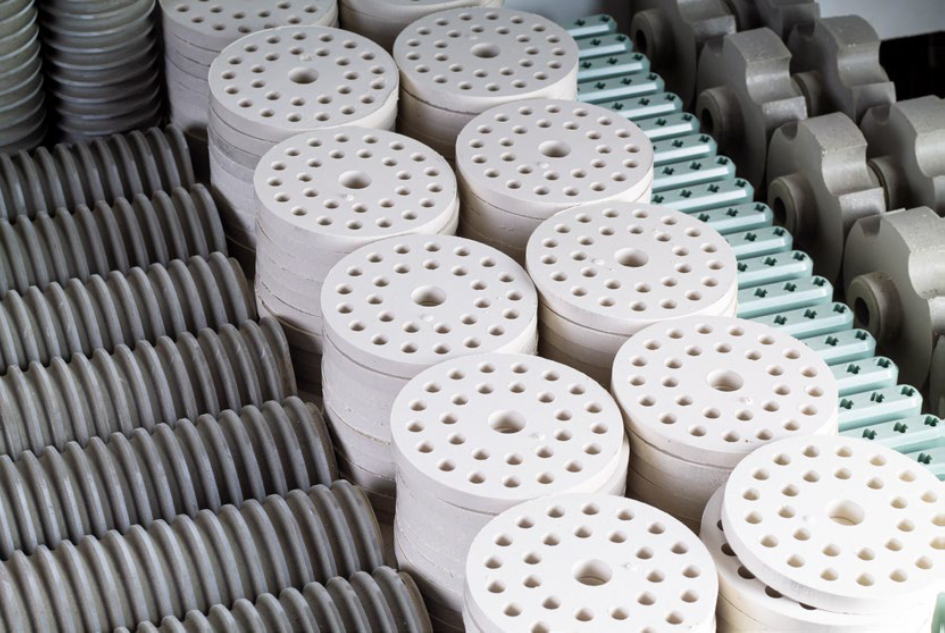

Cordierite Chamotte

Cordierite materials are insulating materials, according to standard IEC 60 672 classified in group C 400 – alkaline earth alumina silicates and C 500 – porous alumina silicates. Talc, kaolin, alumina and MgO are the raw materials used in cordierite ceramics production.

Alkaline earth – aluminosilicates and zircon porcelain C400

- C 410 nonporous cordierite material Cordierite, dense

- C 420 Celsian, dense

- C 430 basic calcium oxide, dense

- C 440 basic zircon, dense

Porous aluminosilicates and magnesium aluminosilicates

- C510 porous cordierit

- C511 magnesium-aluminosilicate based

- C512 magnesium aluminosilicate based

- C520 porous cordierit

- C530 porous cordieri

The most used porcelain in industry is:

C 410: non-porous

C 510: porous cordierite,

C 520: porous cordierite,

C 530: porous cordierite for applications at higher temperatures

It has been widely used in applications where thermal shock resistance is important, as it has low thermal conductivity and low thermal expansion rate. It is perfectly suited for the production of heat holders, refractory plates and other similar products. As a lightweight structural material, thermal insulation material or catalyst carrier, cordierite-based porous ceramics have become increasingly important.

Manufacturing method:

dry pressing, injection molding, extrusion, slip casting

Characteristic properties of steatite:

high specific resistance at high temperatures, high resistance to thermal shock, high temperature resistance, low coefficient of thermal expansion